Applications of 3D Printing Across Various Fields

3D printing, also known as additive manufacturing, has revolutionized numerous industries by enabling the creation of complex structures and products directly from digital models. This technology builds objects layer by layer, offering unparalleled design flexibility and efficiency. Below are some of the key fields where 3D printing has made a significant impact:

1. Healthcare and Medicine

Prosthetics and Orthotics: 3D printing allows for the customization of prosthetic limbs and orthotic devices to fit individual patients perfectly. This results in more comfortable and effective solutions for those needing physical aids.

Surgical Planning and Guides: Surgeons use 3D-printed models of patient-specific organs or bones to plan complex surgeries. Custom surgical guides, created with 3D printing, help increase precision during operations.

Bioprinting: This advanced form of 3D printing involves creating tissue and organ structures with bio-inks composed of living cells. While still in the experimental stage, bioprinting holds promise for organ transplantation and regenerative medicine.

Dental Applications: 3D printing is widely used in dentistry to create custom dental implants, crowns, bridges, and orthodontic appliances, providing accurate and rapid solutions for dental treatments.

2. Aerospace and Aviation

Component Manufacturing: The aerospace industry leverages 3D printing to produce lightweight, complex components with minimal waste. These parts often feature designs that are impossible or very difficult to achieve with traditional manufacturing methods.

Prototyping and Testing: 3D printing is used to quickly produce prototypes for new aerospace parts, allowing for rapid testing and iteration. This accelerates the development process and reduces costs.

Tooling: Custom tools and jigs for aircraft assembly and maintenance can be produced more quickly and cost-effectively with 3D printing, enhancing production efficiency.

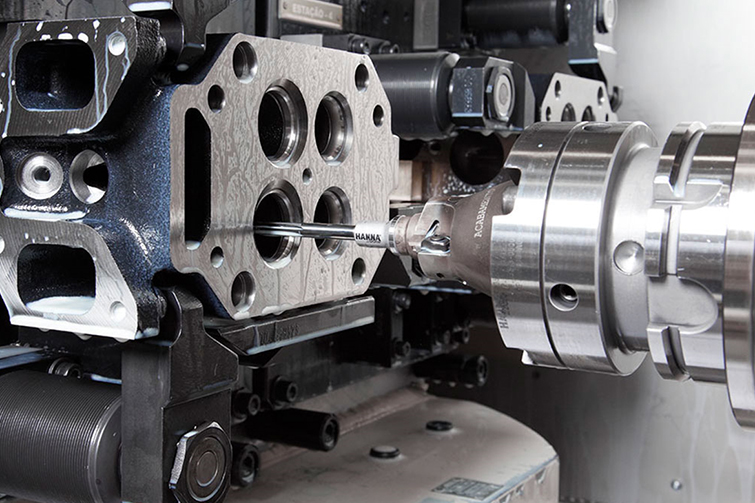

3. Automotive Industry

Rapid Prototyping: Automakers use 3D printing to create prototypes of parts and assemblies quickly. This speeds up the design process and allows for more iterations, leading to better final products.

Custom Parts and Tooling: 3D printing enables the production of custom and low-volume parts that would be costly and time-consuming to produce with traditional methods. It is also used for creating specialized tools and fixtures for the manufacturing process.

End-Use Parts: In some cases, 3D printing is used to manufacture end-use parts, especially for high-performance or custom vehicles. This includes components like air ducts, interior parts, and even entire chassis.

4. Consumer Goods

Fashion and Jewelry: Designers use 3D printing to create intricate jewelry pieces and fashion accessories that are difficult or impossible to make with traditional methods. This includes personalized jewelry, avant-garde fashion pieces, and custom-fit items.

Footwear: Companies like Adidas and Nike use 3D printing to create custom insoles and shoe components that improve performance and comfort. This technology also allows for rapid prototyping and design iterations.

Home Décor and Furniture: 3D printing enables the production of custom home décor items and furniture with unique designs. It allows for the creation of complex, aesthetically pleasing structures that are not feasible with conventional manufacturing.

5. Architecture and Construction

Modeling and Prototyping: Architects use 3D printing to create detailed scale models of buildings and structures, which helps in visualization, presentation, and planning.

Construction: Large-scale 3D printers are now being used to construct buildings. This innovative approach can produce houses and other structures more quickly and cost-effectively than traditional construction methods.

Interior Design: Custom fixtures, furniture, and decorative elements for buildings can be created with 3D printing, offering unique and bespoke design options.

6. Education and Research

Educational Tools: Schools and universities use 3D printers to create educational models and tools, enhancing the learning experience in subjects like engineering, biology, and art.

Research Prototyping: Researchers use 3D printing to produce prototypes and experimental devices quickly. This facilitates innovation and the testing of new concepts across various fields, including materials science and biotechnology.

STEM Education: 3D printing is integral to STEM (Science, Technology, Engineering, and Mathematics) education, allowing students to bring their ideas to life and understand complex concepts through hands-on projects.

7. Art and Entertainment

Props and Costumes: The film and entertainment industry uses 3D printing to create detailed props, costumes, and set pieces. This technology allows for rapid production and customization of items needed for movies, theater, and TV shows.

Artistic Creations: Artists employ 3D printing to realize intricate and innovative designs that push the boundaries of traditional art forms. This includes sculptures, installations, and digital artworks.

Animation and Gaming: In animation and gaming, 3D printing is used to create detailed character models and scene components, facilitating the development of physical replicas and collectibles.

8. Food Industry

Customized Food Products: 3D printing is making inroads into the culinary world by allowing chefs to create customized and intricate food designs that are impossible with traditional cooking methods. This includes personalized chocolates, complex pasta shapes, and decorative garnishes.

Nutritional Customization: This technology can produce food with tailored nutritional profiles, suitable for specific dietary needs, such as for athletes, elderly individuals, or those with medical conditions.

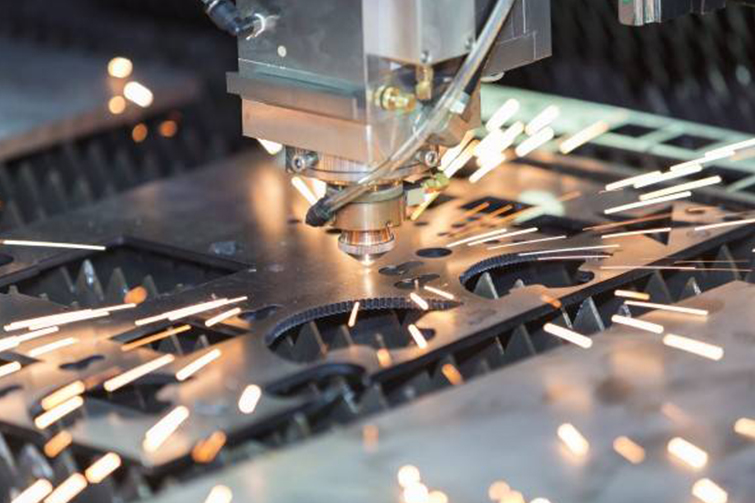

9. Manufacturing and Industrial Applications

Tooling and Molds: 3D printing is used to produce molds and tools for manufacturing processes. These can be created quickly and with high precision, reducing lead times and costs.

Spare Parts and On-Demand Production: Industries use 3D printing to produce spare parts on-demand, minimizing inventory and lead times. This is particularly useful in sectors like aerospace and automotive, where maintaining large inventories of spare parts can be costly.

Customized Solutions: 3D printing allows for the production of customized parts and components tailored to specific applications or client requirements, offering flexibility and adaptability in manufacturing processes.

Conclusion

3D printing is transforming numerous fields by offering innovative solutions that enhance design flexibility, reduce production times, and allow for greater customization. Its applications span from healthcare and aerospace to consumer goods and construction, underscoring its versatility and impact. As the technology continues to evolve, its role in shaping the future of manufacturing and product development will only grow more significant.

Whether in creating life-saving medical devices or producing complex aerospace components, 3D printing is paving the way for a more dynamic and adaptable approach to manufacturing and design.